When it comes to the manufacturing of your plastic parts and products, you actually have the choice of going down a number of routes. You have injection moulding, blow moulding compression moulding, extrusion moulding and rotational moulding that are the most commonly used.

Each of these methods will come with its strengths and weaknesses when it comes to the moulding of your parts and products. However, we wanted to give you our opinion on why injection moulding is the best of them and have provided some of this method’s biggest advantages.

- Better Suited to Parts With Detailed Features

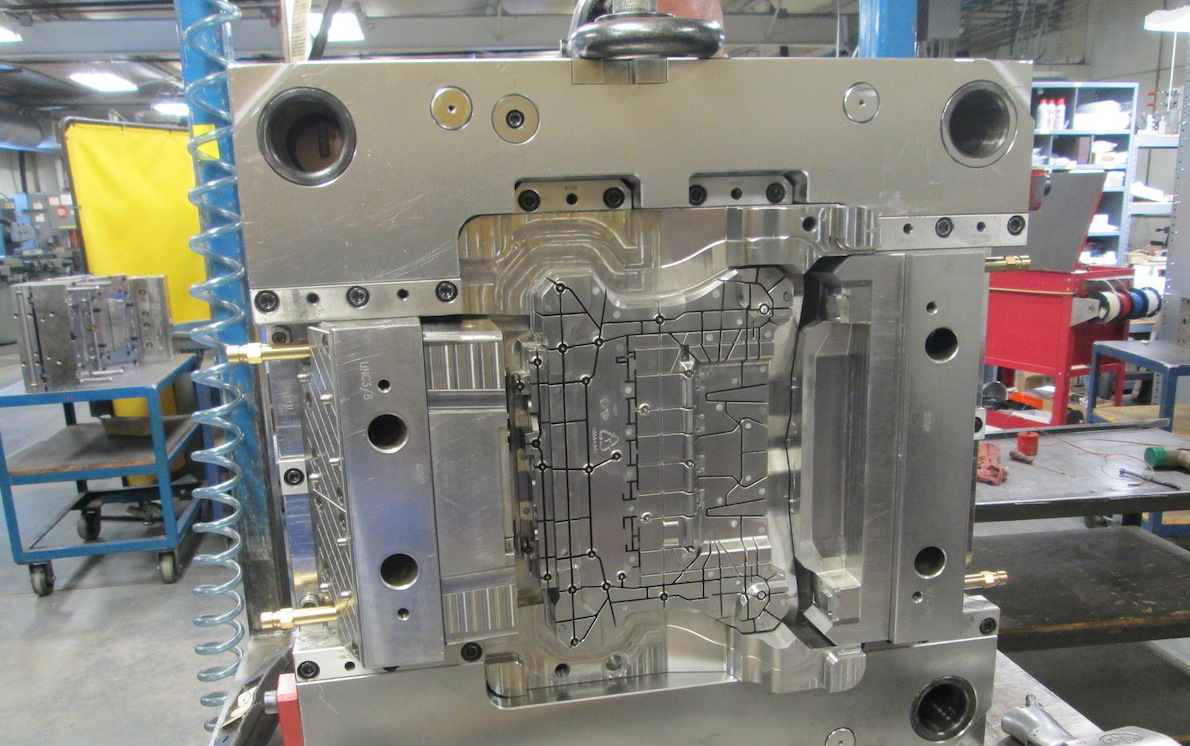

The injection moulding process results in much higher pressures than any other plastic moulding method and therefore means the mould and plastic are pressed together harder. What this means is that any part or product that requires large amounts of detail in its design is better suited to using injection moulding for its creation.

- The Injection Moulding Process is Quicker and More Efficient

Another key advantage to using plastic injection moulding is that it has a higher production output rate than many of the other moulding methods. Once a mould has been designed to match the specifications given by the customer, it can also be used to manufacture more parts or products than most other types of moulds can manage before needing to be replaced.

- Ideal for Parts That Need to Be Strong

Injection moulding is also suited to creating plastic parts and products that need to have added strength. Fillers can be used as part of the process to ensure that the parts have greater strength and durability. This is something that not all other types of moulding have the ability to do.

- Injection Moulding Allows the Simultaneous Use of Multiple Plastics

Any part or product that requires multiple types of plastics to be used when moulding is also suited to injection moulding. Through co-injection moulding, a part can be comprised of multiple types of plastics being used at the same time.

Conclusion

As you can see, injection moulding offers a bunch of benefits that many other types of plastic moulding is unable to. The above are just four of the bigger advantages but there are actually a few others such as the ability for mouldings to be automated. This means that the overheads incurred are much cheaper than those of most other types of moulding techniques.

So when it comes to choosing a plastic moulding method to use for your parts and products, injection moulding is probably one that should be right at the top of your list. It is cheaper, more efficient, quicker and can produce moulds with much higher detail.